[Last Updated On: February 7, 2023]

Operational excellence requires continuous change. With smarter improvements, manufacturers can hit targets and reach higher goals by unlocking productivity.

According to McKinsey, operational excellence is “the thoughtful application of new technologies and capabilities that drives productivity throughout an organization and across the entire value chain. From product development and procurement; to manufacturing and the supply chain; and to service operations to capital excellence.” Operational excellence is also a mindset rooted in company culture and guiding principles that empowers your workforce for continuous improvement across the plant.

Like all of your objectives, achieving operational excellence in manufacturing can have ups and downs. A big challenge? Change management.

Because of this, it’s essential to use proven frameworks and a team-driven approach. Read on to learn how to get started on achieving operational excellence in your own plant.

This guide includes:

- What is Operational Excellence in Manufacturing?

- How to Achieve Operational Excellence in Your Own Plant

- Include the frontline in quality design

- Monitor quality control on the shop floor

- Practice continuous improvement across your organization

- Implement a manufacturing excellence system

- Operational excellence use cases for Raven

- Increased customer satisfaction

- Increased efficiency

- Cost savings

- Achieve operational excellence with Raven

What is operational excellence in manufacturing?

Operational excellence gives manufacturers a framework to implement growth strategies stronger than competitors and help them meet three key goals: operational, financial and people-oriented.

- Operational-oriented goals: Goals that focus on increasing company productivity or improving quality.

- Financial-oriented goals: Goals that focus on boosting financial metrics through more efficient operations and stronger client interactions and sales.

- People-oriented goals: Goals focus on creating a positive workforce that excels in production while putting their workers first.

Operational excellence in manufacturing is the point at which each and every employee in your factory can see the flow of value to your customer, and fix that flow before it breaks down. From a process perspective, continuous improvement, lean manufacturing and Six Sigma are included here.

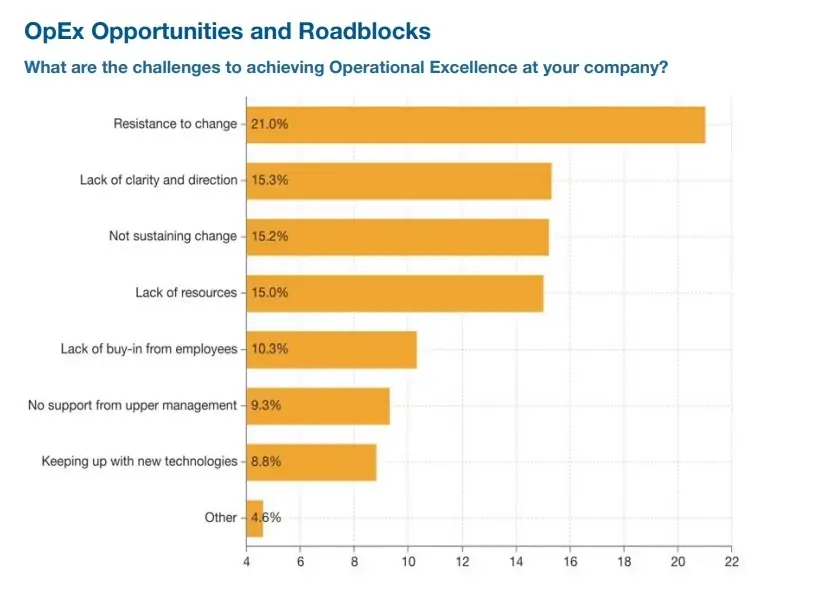

When manufacturing excellence systems are put in place to support operators, supervisors, and their teams, it sets them up for success. Manufacturers can efficiently hit targets and celebrate their wins. But, sometimes it’s a long and tricky process. The OpEx Annual survey noted that resistance to change is the most common challenge industry leaders come across (21% of respondents).

This result isn’t new. Every year since 2017, resistance to change has been the top challenge to achieving operational excellence in manufacturing. But, when quality improvements and a performance mindset are used with your manufacturing excellence systems, then change is better managed across factories.

How to achieve operational excellence in your own plant

The ideal approach to achieve operational excellence in manufacturing is to manage change with a focus on quality improvements and a fresh perspective. Consultant Andrew Miller shared his thoughts with Industry Week noting “Operational excellence is a mindset, not a methodology. It is the pursuit of finding ways to improve performance and profits. It is finding money and performance boosts in areas that organizations don’t normally look.”

On top of an operational excellence mindset, shop floor teams need to look at quality as a key priority in their day-to-day. Quality in terms of shop floor design and planning, maintenance, and of course, production. Here are a few considerations for your operational excellence program:

- Include the frontline in quality design

- Monitor quality control on the shop floor

- Practice continuous improvement across your organization

- Implement a manufacturing excellence system

Include the frontline in quality design

Quality design and planning includes any new or existing methods, processes or procedures. Whenever new designs and workflows are tested in your plant, it’s important to include your operators on your performance audit.

Using an intuitive downtime tagging interface, like Raven, allows operators to provide meaningful context on what’s happening on their lines. This real-time visibility into new and existing production processes helps to identify bottlenecks and slowdowns.

A frontline-friendly system engages operators and includes their ideas throughout the continuous improvement process. This supports a collaborative environment where both operators and supervisors can identify where design modifications are needed. With the best design, the best product can be produced.

Monitor quality control on the shop floor

Having effective quality control measures that shop floor workers understand and use, helps ensure production is constantly monitored. Quality control measures can include spreadsheets, whiteboards, team stand-ups, technology, or classic pen and paper to track data and notes.

When operators are enabled to provide meaningful context to what’s happening on a specific process, then inconsistencies that impact quality can be flagged to notify supervisors in real-time. To make control measures easier and more efficient, Industry 4.0 solutions enable frontline teams to work smarter, resolve the root cause of issues to reduce downtime and increase their capacity to hit production targets.

The quality standards of a product can also be improved with ongoing changes to the processes with help from the frontline.

Practice continuous improvement across your organization

Continuous improvement is a process of discovery and change for increased production efficiency and ongoing growth and development for your factory’s workforce.

Shop floor teams need to have two-way conversations so they’re on the same page and using the same data. In addition, when the frontline is included in these continuous improvement strategies, they have more meaning to their day-to-day on top of optimizing processes that could include changeover time and maintenance speed.

The result? An engaged frontline that has the confidence to help uncover productivity improvements and see the value of their hard work.

Operational excellence in production processes is most successful when quality principles focus on design, control and continuous improvement. But, an effective implementation strategy is also needed to help manufacturers reach their biggest business goals.

Implement a manufacturing excellence system

When there are dozens of assets across hundreds of SKUs and suppliers, it’s difficult to manually assess all of the factors impacting performance. Operational excellence managers can get actionable data to manage production by pulling information from machines into real-time insights using digital OEE solutions.

Technology, like Raven, helps you manage increasing production pressures and drive operational excellence in manufacturing by:

- Getting a strong start to your automation strategy with a focus on team collaboration

- Including input from the frontline workers so operators and supervisors have real-time visibility into lines

- Creating sustainable operational excellence processes to engage operators to provide human context about what’s occurring on the shop floor

The outcome is a team that makes confident, data-led productivity improvements.

Operational excellence use cases for Raven

The top three drivers that improve operations are: higher customer satisfaction, greater efficiency, and cost savings. Using both Raven’s software and success team, manufacturing companies have seen some impressive results in improving their operations with these drivers. We wanted to share a couple of shop floor stories below:

Increased customer satisfaction

By using Raven, Renaissance Lakewood was able to increase customer satisfaction through full visibility into their production lines. Operators were engaged to easily tag downtime using a touch of a button on Raven’s HMI and had real-time insights that mattered to them at their fingertips. The data was used to create live production dashboards and automated reports.

“Renaissance was pleased by how responsive our clients, that were using Raven on their lines, were to the production data they had. Without having to “gown up”, we could talk them through what we’re producing for the day.”

– Justin Brennan, Director of Operational Excellence at Renaissance Lakewood, LLC

Another part of the plant operations piece having a significant impact on operational excellence is production efficiency.

Increased efficiency

Using Raven, Stanley Black & Decker Warrington had real-time analytics that were used as a consistent audit trail, helping determine where to focus improvement efficiencies across their shop floor.

With a live overview of their lines, Stanley Black & Decker Warrington knew how machines and their frontline were performing. Using one source of truth, the entire team increased their awareness around downtime to help identify daily operational improvements.

Leaderboards and gamification processes were also used to boost focus on the shop floor with:

- End-of-line dashboards on iPads and TVs to display progress towards production targets

- Some friendly competition for achieving shift performance goals to keep the frontline on track

With increased efficiency on the shop floor comes cost savings.

Cost savings

Lester Buildings leveraged Raven’s downtime tagging feature to empower their frontline in their day-to-day work. Operators were enabled to provide meaningful context that the machine alone was unable to do, adding more awareness and purpose to their responsibilities. The operations team could see what positive impact and results they were driving on their lines with their existing team members and machines.

Lester Buildings reported increased revenue by 34%, raised their plant worker salaries by 24% and made product assembly faster.

Achieve operational excellence with Raven

The combination of people, technology and process improvements shows proven success. When OpEx strategies and programs work, manufacturing teams win. Leading manufacturers are using Raven to achieve operational excellence in their factories and help give them competitive advantage. To see how you and your team can gain a competitive edge, book a demo with our team here.