Achieve operational excellence in your factory with Raven as your competitive advantage.

Trusted by leading manufacturers worldwide:

Accelerating plant performance goes beyond your basic OEE metrics

There is no one-size-fits-all approach to mastering operational excellence, but it does require ongoing OEE measurement and process adaptations. Taking a data-driven approach to OpEx plays a key part in enabling well-executed improvement initiatives on your shop floor.

Cutting-edge manufacturers, big and small, are prioritizing new tools and technology, purpose-built for the shop floor, to empower their frontline to perform their best and make operations as efficient as possible.

Frontline-Friendly

Become a high-performing shop floor through frontline engagement

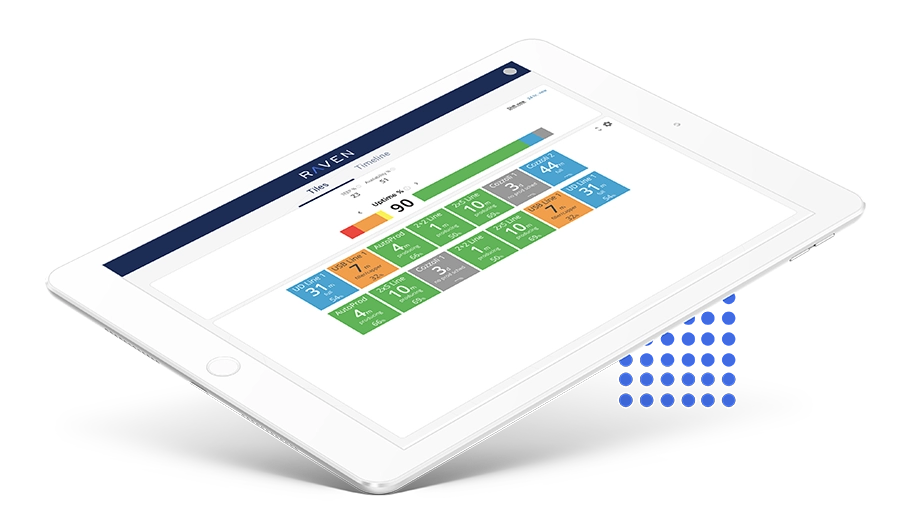

With Raven’s Industry 4.0 software, know exactly when machines are falling behind targets and when equipment downtime occurs, and take immediate action using real-time shop floor insights.

Made for Management

Your manufacturing excellence system for shop floor and OEE performance

When there are dozens of assets across hundreds of SKUs and suppliers, it’s difficult to manually assess all factors impacting performance.

Operational excellence managers can get actionable data insights to manage production while decreasing operational risks and costs, using Raven’s OEE improvement software.

Partners

Better together: Work with one of our top-notch OpEx partners

Our certified OpEx partners can perform on-site operational excellence training to ensure maximum digital adoption and successful change management.

Only pay for what you need

Raven is a low-cost, high-value solution that meets your budget and exceeds your expectations. As a minimal monthly OpEx investment, you won’t get slowed down by lengthy budget approvals. Start fast and scale over time.

View Pricing Plans

Achieve Operational Excellence with Raven

The combination of people, technology and process improvements shows proven success. When OpEx strategies and programs work, manufacturing teams win. Gain a competitive edge with Industry 4.0 software.