Employers — especially managers – know firsthand that engagement plays a large role in productivity in the workplace. A recent survey from Gallup shows that engagement levels in the U.S. alone hover around 30 percent, leaving 70 percent employees disengaged at work. With engagement heavily influencing employee wellbeing, the survey also noted that engaged workers tend to drastically outperform those not-so-engaged employees. This matters on the shop floor.

Savvy, leading manufacturers are now trying to raise the bar when it comes to their team motivation, by integrating gamification elements into the more repetitive aspects of their day-to-day tasks.

In this blog, we breakdown:

- What gamification is

- How gamification works

- Gamification in manufacturing

- How to implement industrial manufacturing in your plant

What is gamification?

Gamification is the application of game theory and design elements to non-game scenarios. While it may seem like an unusual idea, gamification is an increasingly common practice in the workplace — even in manufacturing plants.

A Gartner study revealed that over 70% of Global 2,000 organizations were planning on having at least one “gamified” application implemented by 2014, and technology has come such a long way since then. Gamification isn’t just for engagement either. It can provide invaluable data and insight for teams and organizations to use for continuous improvement and increased performance. It’s important to note that gamification shouldn’t be confused with “games”, which could be distracting or dangerous on the factory floor.

How does gamification work?

The gamification concept mirrors the same science as video games, which are designed to activate the reward centres of the brain. Consumers caught onto the trend earlier than workplaces, with connected wearables like smart watches — turning daily activities such as walking into games to collect special badges and challenge friends/family. Gamification in the workplace operates in the same way by linking output achievements with rewards.

Given the adoption of gamified experiences in consumer products (think of Fitbit or Foursquare, for example), the step towards gamifying tasks on the shop floor doesn’t seem so farfetched. Games measure and motivate, but it’s the one area where success or failure isn’t taken personally. After all, it’s just a game. Effective games are fun and motivational without making workers feel guilty.

As an overarching principle, gamification works best if you can identify a group that is already motivated by something that can be measured.For example, a morning shift, if they choose, can compare with other shifts in terms of performance or turnover time. Alternatively, operators can create friendly competitions by tracking unplanned downtime. By making this element visible, you can often drive the behavior by making it visible. Uncovering measurable objectives in work will kickstart your industrial gamification potential in your plant.

How does gamification fit into manufacturing?

To the casual observer, the typical manufacturing production line seems like a place with no room for games. There doesn’t seem to be a place for creativity or game design in manufacturing, or in this case, industrial gamification. It’s highly repetitive work, tightly controlled and with little variation. Employees work in shifts with a focus on meeting production quotas while maintaining high quality output. It’s work that requires consistency, focus and efficiency.

But your people — your frontline workers — are your most valuable resource, playing a crucial role in the operations and sustainability of your plant.

Leading manufacturing organizations that understand their frontline workers will attract the best people and thrive in the future. Manufacturers have to adapt their workplaces, make them more attractive, the work more engaging, and the time spent on the shop floor more impactful. Your people also want recognition or else they’ll leave. Introducing industrial gamification at your plant is a great tool for achieving these things and improving employee retention.

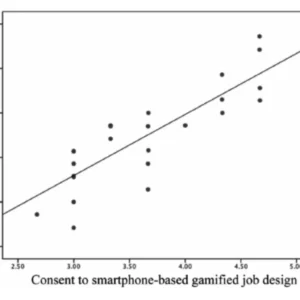

A study looked at the effect of smartphone-based gamification on typical CNC machine operational jobs. The research measures job satisfaction, job motivation and operational performance. The study examined the application of gamification to manufacturing work and whether it helps to provide a more human and enjoyable work experience for CNC machine operators.

They confirmed that games (specifically smartphone-based games) are capable of enhancing job motivation, satisfaction and performance for CNC operators. The study also highlighted a positive correlation between an operator’s willingness to embrace the game (referred to as “consent”) and their job motivation. The more an operator was enthusiastically engaged with the game, the higher their motivation in performing tasks. The plus for your plant? Companies with highly engaged employees tend to outperform those without engagement by 202%.

This should be no surprise to anyone who has played Angry Birds or other rewards-based apps – games make repetitive tasks fun.

How to include gamification in manufacturing

Industrial gamification — with a combination of big data, analytics, IIoT and smart tools of today — will help improve efficiency, motivate employees, encourage healthy competition and reward high performers throughout your plant. Not only can games help your frontline workers retain information and processes more efficiently, but it can also improve relationships on the floor. Ready to gamify some of your operations?

Here are 5 considerations to get your started with gamification in manufacturing:

- What’s measured is managed

- Keep it simple

- Get to know your team

- Make it optional

- Celebrate and reward

1. What’s measured is managed

The old adage is true; if you want to change something, ensure it’s measured. Spend some time figuring out which areas of the production line could use improvements and measure those first. Back your decision-making process with the data and try to resist assumptions. The truth is always in the data.

2. Keep it simple

Games have perimeters and rules. Same with industrial gamification — so try your best not to overthink it. Explore gaming options with a narrow focus of evaluation, like speed or output. Additionally, make the rules clear. Your team should know when they’re playing a game and when they are not.

3. Get to know your team

Do you know what motivates your team? Make sure your game resonates with the people you are trying to engage — your frontline workers. This can be done through surveys and meetings, but often good old-fashioned face-to-face conversations work much better. What rewards would inspire them? What do they like or dislike? This input should drive your game design.

Have a younger workforce? Are you hiring more and more millennials? This is a key insight. Of all the generations in the current workforce, millennials grew up with the most leisure time, and gaming has played a significant role in how they interact with the world. Take that into consideration as you develop your industrial gamification plan.

4. Make it optional

This one is simple. Not everyone is motivated by games. Respect those who would prefer to opt out but incentivize those who do want to play.

5. Celebrate and reward

Once you’ve designed and deployed your game, celebrate the wins and reward the players. Throughout the game, common game elements like badges, points, challenges and leaderboards will help motivate your team.

And you defined the rules of the game, but why not break them on occasion? Break them by providing extra rewards/recognition for outstanding performance to encourage your frontline’s best work every day. This will also preserve your gamification efforts and plan while encouraging the best possible work everyday. Big wins from individuals as well as overall teams should be celebrated as a company. After all, the team’s success is your organization’s success.

“Companies with highly engaged employees tend to outperform those without engagement by 202%.”

— Gallup

Empower your frontline with Raven

Our team at Raven understands the day-to-day schedule and responsibilities of frontline workers — and are dedicated to making your lives easier with support every step of the way.