[Last Updated On: February 21, 2023]

In manufacturing, unplanned downtime is the one of the biggest enemy’s of productivity. When unplanned downtime occurs in a specific area or asset, productivity drops to zero. To put it into perspective, research states that downtime costs industrial manufacturers an estimated $50 billion every single year. Because of this, manufacturers face a daily challenge to reduce downtime on the shop floor.

A recent survey shows that 95 percent of respondents reported that predictive maintenance improved at least one key maintenance value driver, with 60 percent seeing a clear improvement in equipment uptime. A production tracking software paired with a frontline-first approach to reducing unplanned downtime are key to sustainable improvement initiatives across your plant. By understanding how you and your team can reduce factory downtime, alongside a determined leadership team committed to finding smart solutions for operational performance, there are tremendous benefits to both company culture and your bottom line.

Read on to learn about:

- The different types of downtime

- The causes of downtime

- 7+ ways to reduce downtime

- How downtime tagging works

- The benefits of using production tracking software

Downtime in manufacturing is the period of time in which a factory, line or process is offline or unavailable. So downtime is when you’re not running or can’t run your assets or equipment. Other terms used for downtime include: idle time or off-line.

Downtime isn’t always bad. For example, if it’s increasing asset life cycles. It all depends on why the asset is down and if you knew the specific reason for the downtime.

What are the causes of downtime?

The causes of downtime can be categorized as planned or unplanned. Planned downtime is when scheduled maintenance, equipment upgrades, software updates, changeover, setup or inspections take place.

On the other hand, unplanned downtime can occur due to a lack of resources, operational errors, software crashes, broken hardware or machinery, component/material wait times or maintenance wait times.

Keep in mind that these reasons only scratch the surface when it comes to the causes of downtime.

7 smart ways to reduce downtime in the plant

Factory downtime is a major contributor to losses in manufacturing as a whole. When plant equipment isn’t functioning, there is 1) no production and 2) no income. Design manufacturer, S. Himmelstein & Co. reported that, approximately 37 percent of businesses said that they were hit with a setback in the production cycle of a critical asset because of downtime.

When the leadership team has committed to ensuring operational equipment effectiveness (OEE), these 7 measures should be taken into consideration to reduce downtime:

- Identify and prioritize critical processes

- Monitor OEE and other key production measurements

- Collect data and visualize the solutions

- Implement a total productive maintenance program that engages all employees

- Make smart decisions for upgrading equipment

- Create a company and plant culture that embraces best practice improvement

- Automate production downtime tracking with technology

1. Identify and prioritize critical process

Identifying and understanding the processes that are critical to your plant and production targets — and ensuring your frontline understands these processes as well — will increase productivity and performance.

2. Monitor OEE and other key production measurements

Once the team is on the same page, establishing OEE monitoring alongside your plant’s other key production measurements will help drive overall manufacturing process improvements. Using automation in process control technologies in combination with lean manufacturing methods will simplify your production downtime tracking and keep these numbers top of mind. Ensure goals are set and frontline workers know the connection between downtime and goals. This will help prioritize responsibilities and can increase their productivity.

3. Collect data and visualize the solutions

Enabling the frontline operators and managers to collect details and notes on the reasons for downtime/uptime in a clear, organized manner will help provide the team with the full picture of where factory downtime occurs. Taking it one step further, having a dashboard or visualization of their input and production downtime tracking, will create a timeline that provides context to downtime. This will again build out that downtime story, visualize possible solutions and allow you to mitigate unnecessary losses.

“Data and Insights are only useful if you have action.”

— Martin Cloake, CEO and Co-Founder, Raven

4. Implement a total productive maintenance program

A total productive maintenance program is implemented to help all employees get into the mindset of putting machinery at the core focus of an operation to maximize its productivity — switching from reactive to proactive. The program at its core should get the point across that the entire team participates in maintenance — rather than just the maintenance team.

This approach uses the skills of all employees and strives to incorporate maintenance into the day-to-day of a plant. For example, running machines with the mindset of “we’ll fix it when it breaks” is not an option with total productive maintenance.

A successful total productive maintenance program requires planning by key stakeholders. For a smooth execution, communication and collaboration between production and maintenance managers are required to plan production and operator resources, in order to limit the effect on cycle time. Well thought-out and planned maintenance programs will have long term benefits that increase OEE while improving frontline worker’s health and safety.

5. Make smart decisions for upgrading equipment

The type and timing of equipment upgrades are vital to maintaining a productive timeline with limited impact on output. The obvious reason to upgrade in a timely manner is to prevent emergency purchases or costly repairs. Ideally, plant equipment upgrades should coincide with a time that would have the least disruption to employee and production schedules — to reduce downtime. When selecting equipment upgrades, you should consider a partner that has remote monitoring to provide added efficiency, as well as health and safety measures.

Finally, to successfully operationalize the upgrade rollout, an equipment downtime analysis can be utilized to plan workflows, manage budgets and organize resources.

6. Create a company and plant culture that embraces best practice improvement

Manufacturers are constantly under stress. And letting this stress reach the frontline can make them feel like they don’t have enough time in their day to complete their daily responsibilities and routine maintenance. A culture like this can steer towards increased error and additional machine repairs.

This is why it’s crucial to have accurate data to help ensure expectations are realistic and continuous improvement is prioritized. Ensuring your employees are motivated and inspired is another big step to reducing downtime in your manufacturing plant.

A company with leadership that supports lean manufacturing methods would include the continuous improvement of best practices in their management processes — which would in turn flow throughout the plants. When operators, plant managers and engineers are collectively involved in continuous improvement initiatives then there is a greater likelihood of embracing best manufacturing practices.

For Martin Cloake, the CEO and Co-Founder of Raven, the importance of having a strong commitment starts at the leadership level. Key stakeholders have to understand the significance of reducing factory downtime by consolidating data sources, understanding trends and looking for smart opportunities to improve processes in the plant — including operator-specific solutions.

7. Automate production downtime tracking with technology

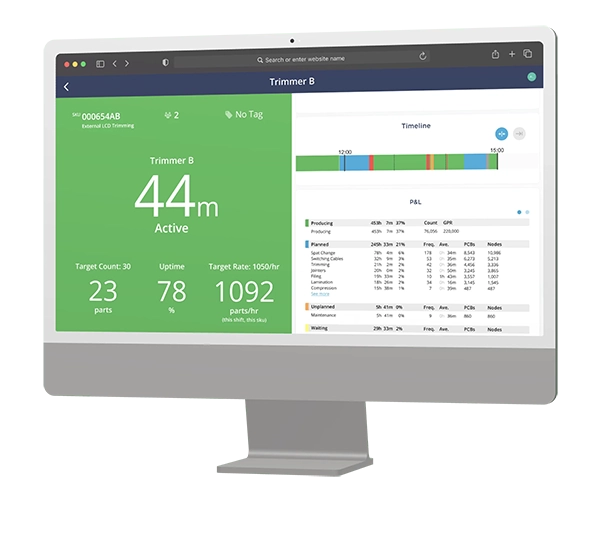

Production downtime tracking software or OEE monitoring technology can help you automatically track machine and frontline worker status using downtime tagging, allowing you to have one source of truth for your data. That way you can get an easy, quick read on downtime so there’s no mystery or outstanding questions on losses. Downtime events can be customized and labeled with all of the key information such as: downtime length, shift, line, machine and product being produced.

What is downtime tagging?

Downtime tagging is the process of tagging periods of downtime in your production line and categorizing them according to the reason they are down. An example of downtime tagging is Raven’s IoT/edge devices that enable operators to ‘tag’ specific instances in their workday timeline such as: lack of production materials, no operator on the floor and equipment maintenance.

Using production tracking software provides real-time visibility to the shop floor from anywhere.

Downtime data is tracked and shown instantly on the dashboard and reports. With real-time data and the right technology, the frontline can address downtime as it happens. Custom alerts and notifications can also be triggered based on certain downtime events.

Designed by experienced manufacturers, Raven combines and analyzes data from machines and operators to provide a meaningful timeline of events — accounting for 100% of production time and losses. Smart devices placed on your lines, replace pen-and-paper tasks and help operators tag the exact reason for downtime and inefficiencies, with the touch of a button.