According to The Manufacturing Institute’s Engagement and Retention Study, employees who feel valued are more than four times as likely to report high levels of work engagement (59% versus 13%). This plays an important role in determining a positive mindset on the factory floor.

In this blog, consisting of two parts (See Part 1), we focus on the frontline-first approach to implementing successful continuous improvement practices, including a summary of the recent fireside chat between Martin Cloake, CEO at Raven and Justin Brennan, Director of Operational Excellence at Renaissance Lakewood.

Justin Brennan shares his experience using Raven, how Raven helped transform the frontline’s mindset, and key continuous improvement wins Renaissance has celebrated to date with a focus on:

- Collecting important operator context to understand the root cause of downtime and losses

- Developing successful initiatives for continuous improvement in manufacturing

- Achieving results with accurate data analytics and team insights

Question #7: Can you provide a specific example of when Raven enabled your operators to have a voice and you were able to demonstrate your belief in them?

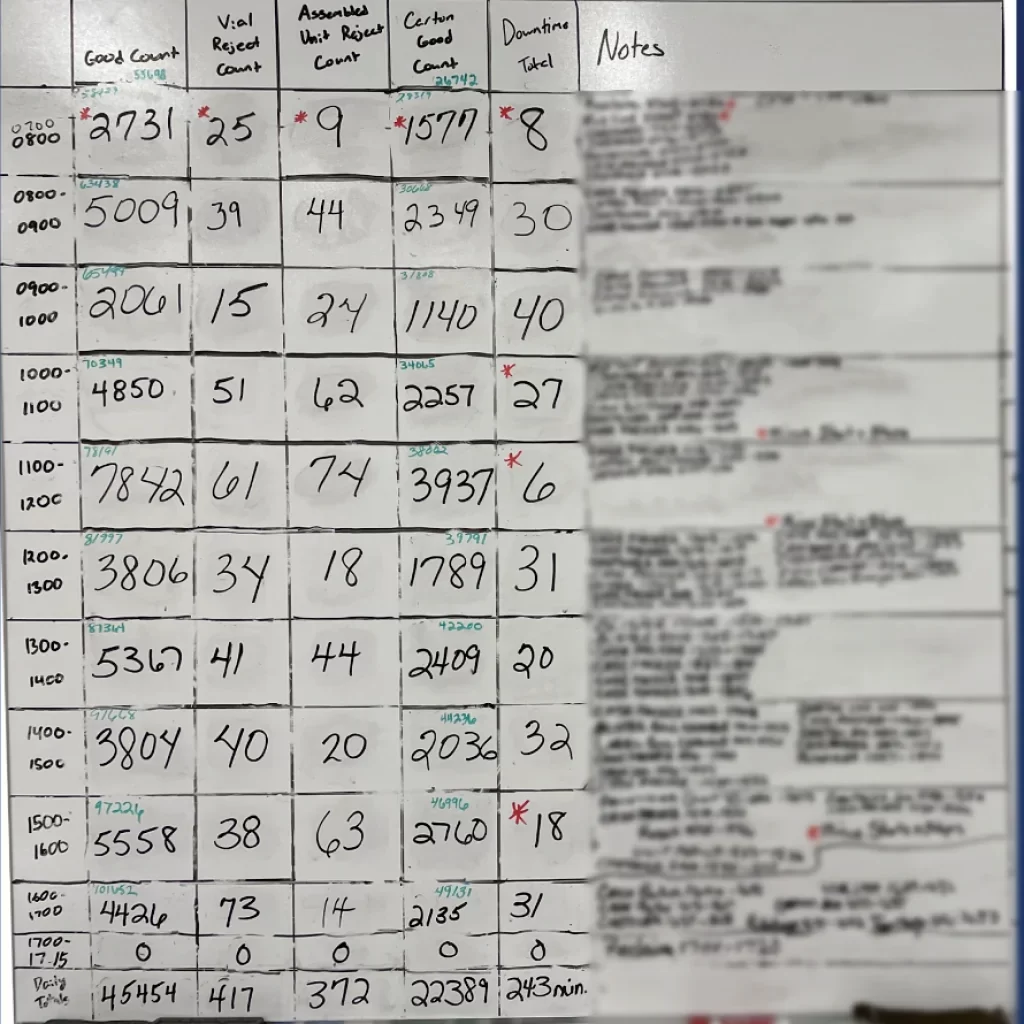

Answer: While we were qualifying a line, we took pictures of a whiteboard for reference. I noticed the whiteboard had an immense amount of details written out, yet the pictures weren’t doing it justice because at the end of the day, they weren’t digitized or kept for historical reference. So, I wondered if this process of whiteboard, to pictures, to trash was a huge waste — the operators agreed.

These are some of the steps we took to transition from data collection with a whiteboard to enabling operators to use Raven on the lines, to provide important details on production losses and downtime:

- We decided to build our own information tracking tool within Excel. We started capturing the data in a very structured fashion, using a defined asset hierarchy with set downtime rules using a tablet that links to an Excel spreadsheet. Once the production information had been tracked, another associate aggregated all the data.

- In conjunction with the engineering team, we held a weekly team meeting to review downtime. The 30 minute huddle, that took away from production time, gave us valuable insight into both short and long-term projects. I was amazed at the numerous off-shift suggestions and comments that demonstrated a significant level of frontline engagement and ownership.

- Even though the Excel tool we built solved other issues including historical data, new challenges arose like data quality, version control and software entropy. So, our next step was to build something more robust. Instead of rebuilding, we talked with our frontline and shared Raven’s use case on other packaging lines in our plant. The operators said, “Wow, this is fantastic!”.

- Once Raven was quickly implemented on our other lines, it became a game changer in the sense of giving our teams real-time visibility into production, but also the consistent capture of downtime. Our frontline teams have immediate access to the data once we go live on the newer lines, which is something I’m incredibly excited about. The frontline teams and operators are engaging because they are part of the solution, and we care about their ideas and observations.

Raven dashboards installed on lines at Renaissance to quickly identify process upsets and dynamic bottlenecks to ensure maximum throughput.

Question #8: What kind of results and performance have you seen so far at Renaissance, using Raven?

Answer: The frontline team, working on the most recent line we deployed Raven on, was amazed to report record-setting performance. We’ve also hit record-setting performance on some of our other billing and packaging lines. It’s been a direct result of day in and day out engagement by the operators, the engineers and mechanics, and all of the other teams contributing to the organization.

Some specific examples of when the data provided an invaluable level of insight into where we need to focus our continuous improvement efforts:

- Based on the complete production timeline we captured, more meaningful discussions occurred and through those data-led conversations, we recognized a shift in the downtime bottleneck. If we see more minor stops, or if we see bigger buckets starting to develop in areas that weren’t there prior, we know to get a mechanic or an engineer to look at the issues as soon as possible.

- Now, we’re starting to use Raven’s timeline to drive our maintenance practices, improve our preventive maintenance practices, and do some work on condition monitoring.

- We were also shocked by how responsive our clients were to the production data we now have. Essentially, without having to “gown up”, we can talk them through what we’re producing for the day. We share Raven’s dashboards and reports and can say, “Look, this is your line, running your product”. Paired with video, it’s like you’re actually standing in front of the lines on the shop floor.

Question #9: What has been your biggest pleasant surprise throughout your continuous improvement in manufacturing journey?

Answer: There’s been a lot of pleasant surprises. The one that surprised us most was the high level of engagement with the Raven team. Raven’s Customer Value Leads and Engineers show a remarkable level of ownership as we deploy Raven’s software and whenever questions or issues arise. They’re always quick to jump on board. We truly have a partnership with Raven — it’s less about the transaction if you will and more about building a future together.

Question #10: What does the future hold for you and for the team at Renaissance?

Answer: I think the future is incremental. I find that technology is rarely truly revolutionary, and often evolutionary. As we look at this continuous improvement process and strategy, we want to maintain the good things we have going while having honest conversations about what’s falling short.

Our top 3 priorities moving forward include:

- Initiating more frontline training to help our operators realize their strong capabilities to problem solve

- Taking what we’ve learned from Raven and expanding across the rest of our site

- Initiating more real-time constructive conversations both internally and externally, using Raven

Question #11: Does Raven need to interface with the ERP?

Answer: It’s not necessary to connect live to the ERP. To operate Raven without a live connection to the ERP, a lot of information is captured asynchronously. As our continuous improvement strategy evolves, we can create more connections with our other information systems in the manufacturing tech stack. We wanted to make sure that we were getting context from all areas possible and the key with operators was the incremental approach change.

Raven was such a viable and helpful solution for us because we didn’t want to integrate it with our ERP right away. There was no need for us to jump right to the end goal. We wanted a layered solution that wouldn’t impact the validated state of our current software equipment. So Raven provided the ability to do so — without any additional integration on that side.

Read Renaissance case study

Learn how Renaissance transformed their conversations around whiteboard data collection to two-way, data-led discussion with the help of their frontline operators.