While manufacturers strive to measure and improve OEE, 77% of IT leaders don’t trust their plant data — with key data points being lost as a result of pen-and-paper processes for tracking downtime reasons. On top of that, every year poor data quality costs organizations an average $12.9 million. This data lacks critical details or “context” that prevents manufacturers from driving productivity improvements, and by extension, millions of dollars in possible cost savings.

In this blog, Raven CEO, Martin Cloake, COO, Dr. Paul Turner and Director of Operations, Brenda Munyukwi, answer your burning questions from our recent webinar on automated contextualization and how it can solve the critical gap of context on the factory floor.

We’ve summarized their insights here:

- OEE optimization

- Operator engagement

- Automated contextualization

- Continuous improvement

Your questions answered by the experts

Operator engagement for OEE optimization

Question: Besides tracking whether operators are on track to hitting their targets, what is an example of how you engage operators?

Answer: When a supervisor asks an operator a question to better understand details or “for context” to a concern or problem, the answer may vary depending on the person and their relationship. However, the way Raven operates using our Automated Contextualization Technology, we consistently give an operator and their supervisor the best possible answer in terms of relevance and accuracy.

We understand that operators know their equipment well and how their operations should run. They just simply need to communicate their requirements in a quicker, easier way on-the-fly. When operators and supervisors have a solid level of engagement, they often have a competitive attribute. For example, if one shift drives OEE at 85% then the next shift is coming in aiming to exceed the previous shift’s OEE. On top of a little friendly competition, Raven enables stakeholders to view end of shift performance so changeovers become more transparent. For example, when a supervisor arrives for their shift on an early Monday morning, they already know what has taken place or they’re able to quickly find answers rather than undertake a lengthy investigation — flipping through written notes and checking whiteboards. No one is blindly walking into their shift. A game changer.

Question: Once accurate data is available, is there a step-by-step approach you would recommend to manufacturers who are going from not trusting shop floor data to utilizing the data accurately and efficiently (while avoiding analysis paralysis)?

Answer: The first thing to do is to earn trust on the shop floor. In general, operators tend to be less interested in reporting than actually driving positive action. They want to see if they’re interacting with their systems effectively and if they can influence their stakeholders to address their plant concerns. For example, operators would like to see:

- Evidence that their supervisors are more responsive to support requests

- The maintenance team fixing their machines faster

- Leadership making decisions around process changes and technology investments to address issues raised

Ultimately, once data and technology results in action, then the frontline will see improvements and trust can be earned.

Question: How do you use unstructured data to get a deeper perspective on OEE?

Answer: From a downtime reason “tagging” perspective, we believe that operators shouldn’t be required to manually type in downtime reasons as this should be as automated as possible. The factory floor is often not conducive to operators entering unstructured data into digital interfaces so any input required from the operator should be as simple and as seamless as possible for them. This has a double benefit in that it reduces the burden on the operator and simplifies the process for driving insights and actions from analytics. Having said this, in a truly digitally transformed world unstructured data will exist and can potentially contain a wealth of insights on root causes, actions and outcomes that can form an enterprise best-practice repository that is continually learning. By mapping digital finger-prints of events on the factory floor to this knowledge base (filtered through NLP, chatbots and other unstructured analytical tools) technology can help drive additional OEE improvements by accelerating the time between an event and its resolution.

Question: Many manufacturers already know that their data is not clean enough to create robust reports. What does Raven do to ensure the data – especially real-time data – is reliable?

Answer: Anything that has human intervention is subject to errors but they can be minimized. Raven focuses on engagement from the operator via our user experience. Operators want to provide the context because we have made it simple and easy. We pride ourselves as being the app that an operator does not want to delete. This is also where Raven’s Automated Contextualization Technology (ACT) is a game changer. The ability to pull information from your PLCs into real-time data coupled by artificial intelligence, which over time minimizes the operator input requirements, is proven to provide reliable actionable data.

OEE optimization to improve performance

Question: From your experiences, what are some of the motivations or metrics that are important to operators when adopting technology?

Answer: In the moment, operators do not care about OEE itself. Operators want to know if they are on track to hit targets and where they are in their process. Raven is specifically designed as an operator-first interface and platform to reflect learnings from operators. Motivations generally include a) something that provides operators value in their day-to-day and b) there is a clear use and need for the tool. Technology has to earn the right to receive operator engagement – it can’t be a one-way street. The operator expects technology to make their life easier, not load them up with additional new tasks for no perceived benefit on their part. This is why Raven’s hyper-focus on creating an exceptional operator experience is key to the successful adoption of technology by operators and teams on the factory floor.

Question: One of the challenges to capture OEE is speed loss (hard to capture, many variables, constant changes, etc.). How do you view this issue as part of automated contextualization?

Answer: There is a difference between a) microstops, b) running slowly or c) if something else happened. Speed losses often sneak up but could have massive consequences during production. It’s critical to ask operators the most relevant questions to receive the best context in understanding what happened. Speed loss is a key pain point we see our customers dealing with and improving throughput is how Raven can help. Raven uses artificial intelligence through our Automated Contextualization Technology to drive insights that show them how a majority of their speed losses are caused by incomplete tracking.

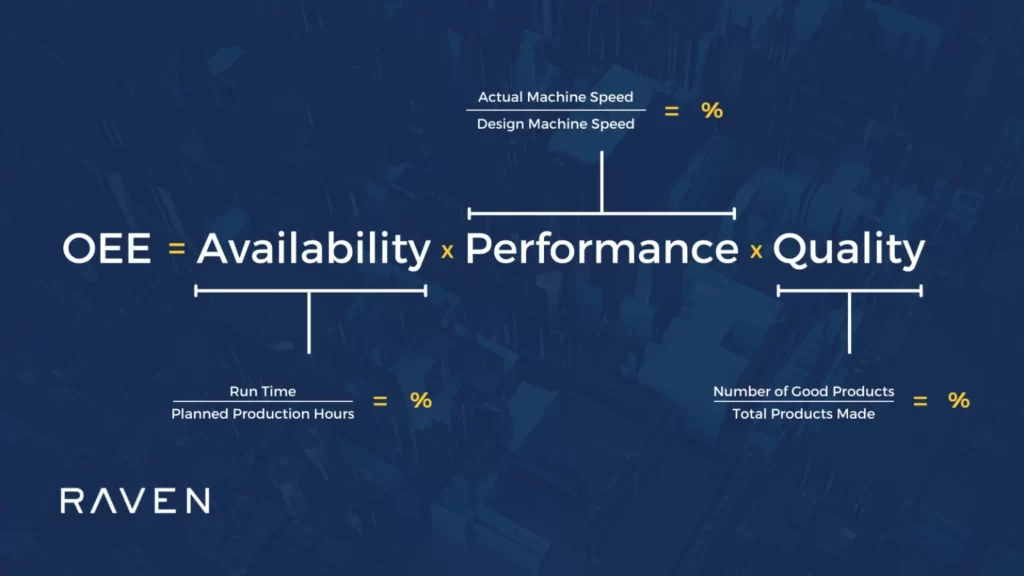

Question: What standard do you use for OEE calculation?

Answer:

Question: What are the most popular ways of improving OEE?

Answer: The majority of our customers in the first 3 months of contextual data collection can make improvements from insights on shift-to-shift inconsistencies, changeover inconsistencies, slow down losses and micro stops. Once a solid baseline is established, it’s also amazing to see how manufacturers are often not operating at the efficiencies they thought they were. We help them look at insights from their data to drive focus improvement projects in their plants.

Automated contextualization to identify opportunities

Question: What is the value of using OEE technology instead of, or in addition to, managing scenarios by walking around and talking to operators?

Answer: As a member of the management team, walking around the shop floor is highly effective. Leaders are often consumed by administrative or reporting tasks that limit their availability. Their time is stretched thin with less capacity to be on the floor to ask operators those key questions.

Context is more than just, “the machine is down because we are waiting for materials”, it’s conditional context that includes, the SKU running on the machine, which shift it ran on, the material suppliers, and what material is being used. When there are dozens of assets across hundreds of SKUs and suppliers, it would be impossible to manually assess all of these different factors impacting performance. Contextualization fits into that broader context, then feeds into analytics and identifies key losses that only AI can find. We’re not replacing in-person conversations that happen on the factory floor. We’re enabling supervisors to spend their time solving problems more efficiently that will make an impact on performance.

Question: As OEE is one of the critical maintenance KPIs, what is the difference between maintenance downtime and operational downtime, and what are their impacts in an equipment/system’s availability, performance/productivity, quality, maintainability, reliability and safety?

Answer: Downtime is a period during which an equipment or machine is not functional or cannot work. It may be due to operational / technical failure, machine adjustment, maintenance, or non-availability of inputs such as materials, labor and power. The difference between maintenance downtime and operational downtime is simply how one chooses to contextualize the downtime. A lot of manufacturers contextualize maintenance downtime as downtime when a scheduled maintenance activity is taking place and often will not include this in the planned production hours. This method allows you to measure your systems availability based on planned production hours. This approach is recommended if you have a robust maintenance scheduling program that has been verified and streamlined.

Question: Can a machine monitoring software also track the specific jobs that it runs in any shift? For example: A mesh is made of vertical and horizontal lines. If the machines are the vertical threads, then every job is like a horizontal thread with a knot at every vertical thread (a machine) that it uses. So I would like to track both machine usage and part flow using your system.

Answer: We can certainly assess the requirements here. Our software is flexible and can offer customizations where feasible. We encourage you to sign up for a demo so we can engage our technical teams for feasibility.

Question: What is your suggestion on how to start thinking differently with OEE? Also, what is your perspective of MTBF and MTTR vs OEE?

Answer: The missing piece for OEE optimization is “automated contextualization”. Operator context can take you so far but it’s a huge task for one person. Automated contextualization will enhance how you drive actionable insights from your data. MTBF and MTTR from our perspective are complementary to OEE. OEE focuses on the equipment availability, performance and quality, and MTBF and MTTR are metrics that indicate the equipment’s reliability and durability. Without context MTBF and MTTR can be just focused on asset reliability/durability. With context, MTTR can be extended to other production delays such as mean time waiting for material and mean change over time which gives a more holistic and granular view of machine status and performance.

Question: What are some examples of how contextualized data identifies opportunities to improve OEE?

Answer: When tracking data, downtime aggregates to one big block of time which makes it challenging to action when you do not know the exact reason or cause of downtime or speed loss. Contextualized data helps you drill down to the specific issues which you can action. Without context the approach taken to downtime is often reactive with teams trying to collect or extract data after-the-fact. This is often time consuming and therefore only focuses on a small percentage of actual margin leakages. With automated contextualization of downtime the information required for action is readily available and prioritized for both the daily meetings and in real-time providing a basis for more proactive opportunities to improve OEE.

Question: Are there differences you see in process versus discrete manufacturing?

Answer: There are no differences in the way we provide our services – we are able to provide contextualized data in real-time in both cases.

Continuous improvement

Question: Job shops are one of the most complex manufacturing systems. How does your technology impact such complex production systems?

Answer: We are in the business of continuous improvement so Raven also takes the need to continuously improve our product to meet & exceed customer needs seriously. We have a few use cases for complex production systems and once approached, our team will evaluate the feasibility. It’s amazing to see the quick turnarounds we can make when we have an engaged customer who is willing to be a partner in the beta process.

Question: We have been collecting data for a few years now but we want to be able to manipulate/sort the data so we can come up with a game plan for continuous improvement. Will we be able to sort on a longer date range instead of day to day? Without the longer date range, it’s challenging to see trends over a monthly/quarterly/yearly basis.

Answer: This is absolutely on our product roadmap and is resourced. We look forward to sharing with our customers very soon our new platform to allow for easier data sorting and faster downloading. Watch this space!

Takeaways: why data contextualization is key

Understanding downtime reasons is key for root cause analysis and driving OEE improvements in your factory. By understanding how AI combines operator input and machine data for automated contextualization of downtime and production losses, you can start to close off the critical gap, or missing data context, on your shop floor.

Here’s a snapshot of some of the webinar takeaways:

- Empower your operators with a way to communicate their requirements simply, in real-time and allow for a quick response from stakeholders.

- Ask operators relevant questions to receive the clear context you need for continuous improvement efforts across your plant. For example, what are you waiting for? Is it maintenance, materials or backup on the line?

- Automated Contextualization provides manufacturers with accurate data that drives action and empowers the frontline to make confident decisions.

- When you combine context from structured data in the MES, ERP and MRP with context provided by operators, you can review operational performance from multiple viewpoints.

- Improve OEE with critical context for 100% visibility of downtime and production losses using Raven.

To get the full rundown, watch the webinar in full on your own time here.